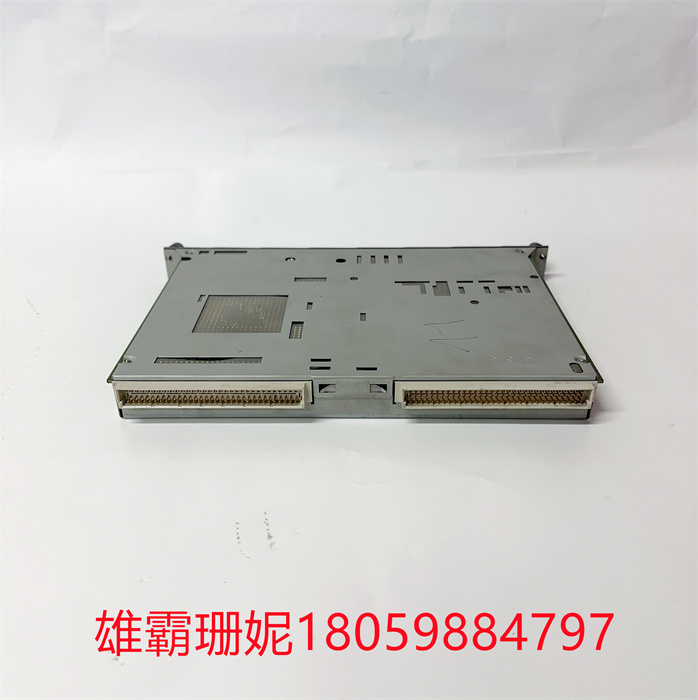

KEBA FB201 工控模块

所谓涡流探伤是基于电磁感应原理,当把通有交变电流的线圈(激磁线圈)靠近导电物体时,线圈产生的交变磁场会在导电体中感应出涡电流,该涡电流的分布及大小除了与激磁条件有关外,还与导电体本身的电导率、磁导率、导电体的形状与尺寸、导电体与激磁线圈间的距离、导电体表面或近表面缺陷的存在或组织变化等都有密切关系。涡电流本身也要产生交变磁场,通过检测其交变磁场的变化,可以达到对导电体检测的目的。因此,利用涡流探伤技术,可以检测导电物体上的表面和近表面缺陷、涂镀层厚度、热处理质量(如淬火透入深度、硬化层厚度、硬度等)以及材料牌号分选等等。

退磁的方法很多:1.将钢材加热到居里温度以上(铁的居里温度为摄氏769度),当然此温度状态下,材料受到热处理,材料的性能会发生改变.2.可以将材料置于交流线圈前,使其缓慢通过交流线圈,直至离开线圈1米以外,对于重型或大型工件,也可以将交流线圈套在工件上,通电时将线圈缓慢通过并远离工件,在距工件1米以外段电.3.直流换向衰减法或频电流自动退磁,也是可以选用的方法.

随着我们继续迈向互联工业的未来,网络安全仍然是许多组织的一个突出问题。在这种情况下,霍尼韦尔最近在6月举行的2017年霍尼韦尔用户组美洲会议上对工业网络安全做出了重大承诺。Honeywell Industrial Cyber Security for Critical infra structure & IIoT副总裁兼总经理Jeff Zindel和他的员工在一次私人简报会上讨论了这项工作。“对于工业网络安全业务来说,这是令人难以置信的伟大的一年…巨大的进步,”Zindel说道,“我们真的相信霍尼韦尔是工业网络安全解决方案的领先提供商,并提供一套全面的端到端网络安全解决方案、服务、技术和专注于工业关键基础设施保护的持续支持”。凭借Zindel描述的资源,包括150多名网络安全专业人员,以及许多其他工程师和专家的支持,霍尼韦尔似乎有了一个良好的开端。

KEBA FB201 工控模块

The so-called eddy current flaw detection is based on the principle of electromagnetic induction. When the coil (exciting coil) with alternating current is close to a conductive object, the alternating magnetic field generated by the coil will induce eddy current in the conductor. The distribution and size of the eddy current are closely related to the electrical conductivity and permeability of the conductor itself, the shape and size of the conductor, the distance between the conductor and the exciting coil, and the existence or structural changes of defects on or near the surface of the conductor. The eddy current itself also produces an alternating magnetic field, and the purpose of detecting the conductor can be achieved by detecting the change of its alternating magnetic field. Therefore, eddy current flaw detection technology can be used to detect surface and near-surface defects on conductive objects, coating thickness, heat treatment quality (such as quenching penetration depth, hardened layer thickness, hardness, etc.), material grade sorting and so on.

There are many ways to demagnetize: 1. Heat the steel above the Curie temperature (the Curie temperature of iron is 769 degrees Celsius). Of course, at this temperature, the material will be subjected to heat treatment, and the properties of the material will change. 2. You can put the material in front of the AC coil and make it slowly pass through the AC coil until it is 1 meter away from the coil. For heavy or large workpieces, you can also wrap the AC coil around the workpiece, and slowly pass the coil away from the workpiece when it is energized.

As we continue to move towards the future of the interconnected industry, network security is still a prominent issue for many organizations. In this case, Honeywell recently made a major commitment to industrial network security at the 2017 Honeywell User Group Americas Conference held in June. Jeff Zindel, vice president and general manager of Honeywell Industrial Cyber Security for Critical Infrastructure & IIOT, and his employees discussed this work in a private briefing. "For the industrial network security business, this is an incredibly great year … great progress," Zindel said. "We really believe that Honeywell is a leading provider of industrial network security solutions and provides a comprehensive set of end-to-end network security solutions, services, technologies and continuous support focusing on the protection of key industrial infrastructure." With the resources described by Zindel, including more than 150 network security professionals and the support of many other engineers and experts, Honeywell seems to have a good start.