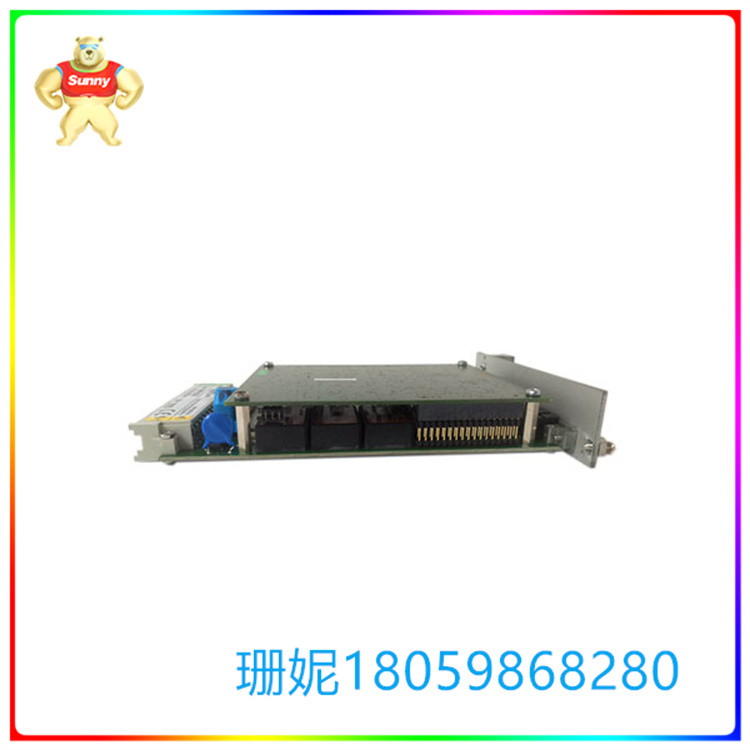

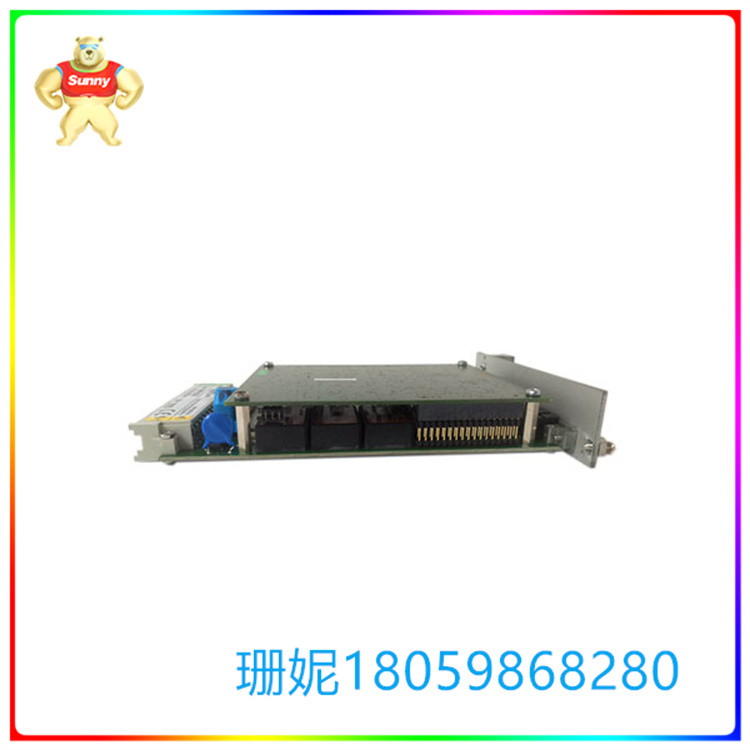

MMS6110 EPRO 双通道轴振动测量模块 涡流传感器信号输入

【产品详情】

1. 信号输入

MMS6110有两路独立的涡流传感器信号输入: SENS 1H(z8)/SENS 1L(z10)和SENS 2H(d8)/SENS 2L(d10)。与之匹配的传感器为德国epro公司生产的PR642X 系列涡流传感器和配套的前置器。也可使用其它厂家生产的同类型传感器。输入电压范围为-1…-22 V dc 。

传感器信号可以在模块前面板上SMB接口处测到。 此外模块还备有键相信号输入(必须大于13V),该信号是速度控制方式及频谱分析所必需的。

2. 信号输出

a. 特征值输出 模块有两路代表特征值的电流输出:I1+(z18)/ I1-(b18)和I2+(z20)/ I2-(b20),可设定为0…20mA或4…20mA。在Smax和Sppmax模式下,两个通道的输出是相同的。 模块有两路代表特征值的0…10 V电压输出EO 1(d14)/ EO 2(d16)。

b. 动态信号输出 模块提供两路0…20 Vpp动态信号输出AC1(z14)/ AC2(z16)用于频谱分析。 0…20 Vpp相当于特征值的量程。

c. 模块提供两路0…10 V dc 电压输出NGL1(z12)/ NGL2(d12)。 该输出与传感器和被测面的距离成正比。

3. 限值监测

a. 报警值 在双通道模式,每个通道可以分别设置报警值和危险值。在Smax和Sppmax模式,两个通道共有一个报警值和一个危险值。报警开关特性为测量值上升时超限触发。为避免测量值在限值附近的变化反复触发报警,可设定报警滞后值,在满量程的1…10%之间选择,开关特性为下降触发。

b. 限值倍增器及倍增系数X 在特殊情况下,如过临界转速时,振动幅值会超限,但机组运行状态正常。为避免不必要的报警或跳机,可在软件中激活限值倍增器功能,并设置倍增系数X(1.00~5.00)。使用此功能时,d18应为低电平。倍增系数X同时影响报警值和危险值。

c. 报警输出 模块给出四个报警输出: 通道1:危险D1-C,D1-E(d26,d28),报警A1-C,A1-E(b26,b28) 通道2:危险D2-C,D2-E(d30,d32),报警A2-C,A2-E(b30,b32)

d. 报警保持功能 使用此功能,报警状态将被保持。只有通过软件中复位命令(Reset latch channel 1/2)才能在报警条件消失后取消报警。

e. 报警输出方式 使用SC-A(报警 d24)和SC-D(危险 z24)时可以选择报警输出方式: - 当SC- 为断路或为高电位(+24 V)时,报警输出为常开。 - 当SC- 为低电位(0 V)时,报警继电器为常闭。 为避免掉电引起报警,便于带电插拔,建议选用报警输出为常开。

f. 禁止报警 在下述情况,报警输出将被禁止: - 模块故障(供电或软件故障)。 - 通电后的延时期,断电和设置后的78秒延时期。 - 模块温度超过危险值。 - 启动外部报警禁止,ES(z22)置于0 V。 - 在限值抑制功能激活时,输入电平低于量程下限0.5V或高于量程上限0.5V。

4. 状态监测

模块不间断地检查测量回路,在发现故障时给予指示,并在必要时闭锁报警输出。 状态指示有三种途径: - 通过前面板“通道正常”指示灯; - 通过“通道正常”输出1 / 2; - 通过计算机及组态软件在Device status 显示。

a. 通道监测 模块检查输入信号的直流电压值。当输入信号超过设定上限0.5V或低于设定下限0.5V时,给出通道错误指示(传感器短路或断路)。

b. 过载监测 当动态信号的幅值超过设定量程时,模块给出过载信息。

MMS6110 EPRO 双通道轴振动测量模块 涡流传感器信号输入

【英文介绍】

1. Signal input

The MMS6110 has two independent eddy current sensor signal inputs: SENS 1H (z8) /SENS 1L (z10) and SENS 2H (d8) /SENS 2L (d10). The matching sensor is the PR642X series eddy current sensor and the supporting preprocessor produced by German epro company. Sensors of the same type produced by other manufacturers can also be used. Input voltage range is -1... -22 V dc.

Sensor signals can be detected at the SMB interface on the front panel of the module. In addition, the module also has a key signal input (must be greater than 13V), which is necessary for speed control mode and spectrum analysis.

2. Signal output

a. The eigenvalue output module has two current outputs representing the eigenvalue: I1+ (z18)/I1- (b18) and I2+ (z20)/I2- (b20), which can be set to 0. 20mA or 4... 20mA. In Smax and Sppmax mode, the output of both channels is the same. The module has two 0's representing the eigenvalue... 10 V voltage output EO 1 (d14)/EO 2 (d16).

b. Dynamic signal output module provides two 0... 20 Vpp dynamic signal output AC1 (z14)/AC2 (z16) for spectrum analysis. 0... 20 Vpp corresponds to the range of eigenvalues.

c. The module provides two 0 channels... 10 V dc voltage output NGL1 (z12)/NGL2 (d12). The output is proportional to the distance between the sensor and the measured surface.

3. Limit monitoring

a. Alarm value in the dual channel mode, each channel can be set respectively alarm value and danger value. In Smax and Sppmax modes, the two channels share one alarm value and one danger value. The alarm switch is triggered when the measured value rises beyond the limit. In order to avoid the change of the measured value near the limit value to trigger the alarm repeatedly, the alarm lag value can be set at 1... Select between 10%, the switch is triggered by the drop.

b. Limit multiplier and multiplication factor X In special cases, such as over the critical speed, the vibration amplitude will exceed the limit, but the unit is operating normally. In order to avoid unnecessary alarm or jump, the limit multiplier function can be activated in the software and the multiplication factor X (1.00~5.00) can be set. When using this feature, d18 should be low. The multiplication factor X affects both the alarm value and the danger value.

c. Alarm output module gives four alarm outputs: Channel 1: Danger D1-C, D1-E (d26, d28), alarm A1-C, A1-E (b26, b28) Channel 2: Danger D2-C, D2-E (d30, d32), alarm A2-C, A2-E (b30, b32)

d. Alarm hold function Using this function, the alarm status will be maintained. Only the Reset latch channel 1/2 command in the software can cancel the alarm after the alarm condition disappears.

e. Alarm output mode When SC-A (alarm d24) and SC-D (danger z24) are used, the alarm output mode can be selected: - When SC- is open or high potential (+24 V), the alarm output is normally open. - When SC- is low potential (0 V), the alarm relay is normally closed. In order to avoid power failure and cause alarm, it is recommended that the alarm output be normally open.

f. Disable alarm output will be disabled in the following cases: - Module failure (power supply or software failure). - Delay period after power on, 78 seconds delay period after power off and setup. - The module temperature exceeds the threshold. - Activate external alarm disable, ES (z22) set at 0V. - When the limit suppression function is activated, the input level is 0.5V below the lower range or 0.5V above the upper range.

4. Condition monitoring

The module continuously checks the measurement loop, gives an indication when a fault is found, and locks the alarm output if necessary. There are three ways to indicate the status: - Through the "Channel Normal" indicator on the front panel; - Output 1/2 through "Channel Normal"; - Display in Device status through computer and configuration software.

a. The channel monitoring module checks the DC voltage of the input signal. When the input signal exceeds the set upper limit of 0.5V or is lower than the set lower limit of 0.5V, the channel error indication (sensor short circuit or open circuit) is given.

b. Overload monitoring When the amplitude of the dynamic signal exceeds the set range, the module gives overload information.

MMS6110 EPRO 双通道轴振动测量模块 涡流传感器信号输入

【其他型号推荐】

| TRICON 3004 | Triconex DCS | 输出模块 | BENTLY 330980-70-00 | 红外线点温计 | Bently Nevada |

| TRICON 8110 | Triconex DCS | 高密度主机箱 | BENTLY 330980-51-05 | I/O 电源 | Bently Nevada |

| TRICON 4211 | Triconex DCS | 远程扩展器模块 | BENTLY 330980-51-00 | 励磁系统电源模块 | Bently Nevada |

| TRICON 3502E | Triconex DCS | 数字输入模块 | BENTLY 330980-50-05 | 控制屏 | Bently Nevada |

| TRICON 3805H | Triconex DCS | 模拟量输出模块 | BENTLY 330980-50-00 | 主控制板 | Bently Nevada |

| TRICON 3601E | Triconex DCS | 数字输出模块 | BENTLY 3309300650205 | 位移变送器 | Bently Nevada |

| TRICON 3501E | Triconex DCS | 数字输入模块 | BENTLY 330930-065-02-00 | 无刷励磁系统 | Bently Nevada |

| TRICON 3601E | Triconex DCS | 数字输出模块 | BENTLY 3309300650000 | 直流调速器控制板 | Bently Nevada |

| TRICON 3703E | Triconex DCS | 模拟输入模块 | BENTLY 330930-045-01-00 | 控制器专用电池 | Bently Nevada |

| TRICON 3700A | Triconex DCS | 模拟输入模块 | BENTLY 330930-045-00-05 | 接口 | Bently Nevada |

| TRICON 3511 | Triconex DCS | 输入脉冲模块 | BENTLY 330930-040-01-00 | 张力控制系统功率板 | Bently Nevada |

| TRICONEX 3664 | Triconex DCS | 数字量输出模块 | BENTLY 3309300400100 | 电池电路板 | Bently Nevada |

| TRICONEX 3451 | Triconex DCS | 模拟输出模块 | BENTLY 330930-040-00-CN | 直流调速器 | Bently Nevada |