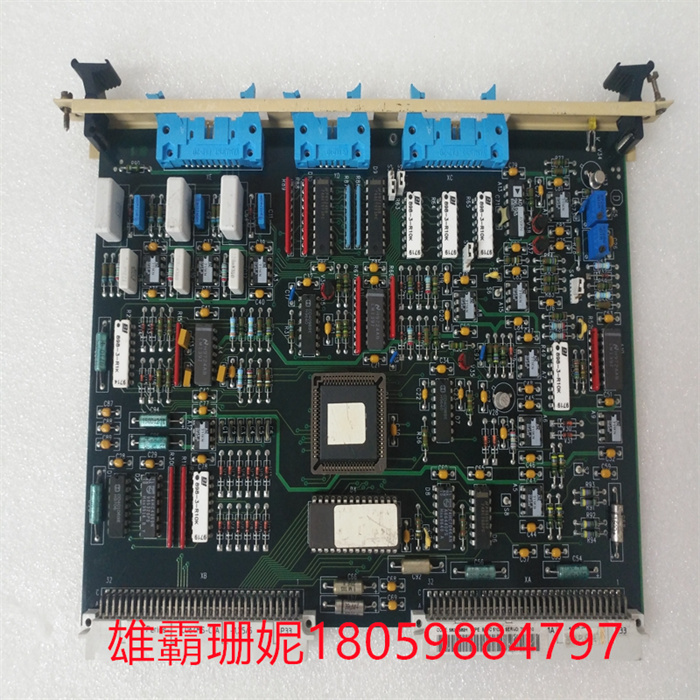

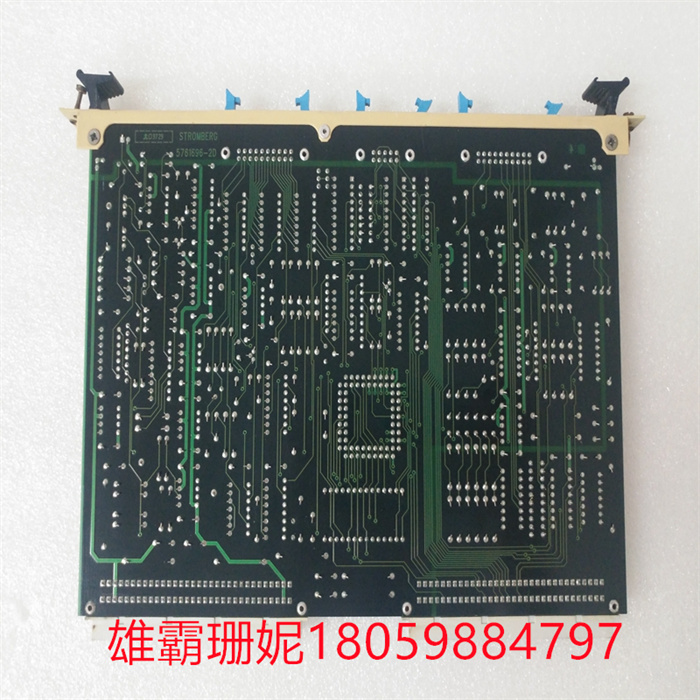

ABB SCYC51020 58052582H 脉冲输入(PI)模块

嵌入式系统包含:硬件层、中间层、系统软件层和应用软件层(1) 硬件层: 嵌入式微处理器、存储器、通用设备接口和I/O接口。嵌入式核心模块 = 微处理器 + 电源电路 + 时钟电路 + 存储器Cache:位于主存和嵌入式微外理器内核之间,存放的是近一段时间微外理器使用多的程序代码和数据。它的主要目标是减小存储器给微处理器内核造成的存储器访问瓶颈,使处理速度。(2) 中间层 (也称为硬件抽象层HAL或者板级支持包BSP)它将系统上层软件和底层硬件分离开来,使系统上层软件开发人员无需关系底层硬件的具体情况,根据BSP层提供的接口开发即可。

BSP有两个特点: 硬件相关性和操作系统相关性。设计一个完整的BSP需要完成两部分工作:嵌入式系统的硬件初始化和BSP功能.片级初始化:纯硬件的初始化过程,把嵌入式微处理器从上电的默认状态逐步设置成系统所要求的工作状态。板级初始化:包合软硬件两部分在内的初始化过程,为随后的系统初始化和应用程序建立硬件和软件的运行环境。

系统级初始化: 以软件为主的初始化过程,进行操作系统的初始化。

高密度继电器开关:模块提供了高密度的继电器开关能力,可同时控制多个继电器通道。它支持多达 128 个继电器通道,适用于需要同时操作多个通道的应用。高速开关操作:该模块具备快速的继电器开关速度,可实现快速的切换和连接操作。它采用了高性能继电器技术,可在毫秒级的时间内完成开关操作,适用于对响应时间要求较高的应用。多种继电器类型: 支持不同类型的继电器,包括通用继电器、矩阵继电器和大功率继电器等。用户可以根据具体需求选择适合的继电器类型,并进行灵活的配置和连接。高电压和高电流测量:该模块支持高电压和高电流的测量应用。它提供了高电压和高电流输入通道,可安全地测量和控制高电压和高电流信号,适用于电力、电子设备测试和控制等应用领域。强大的软件支持模块配备了 NI-DAQmx 驱动软件,提供了丰富的功能和易于使用的编程接口。用户可以使用 LabVIEW、C/C++、Python 等常用编程语言进行编程和控制,方便快速地实现继电器开关操作。

适用于 Advant Master DCS 的 Advant Controller 160 支持和迁移适用于 Advant Master DCS 的 ABB Advant Controller 160,这是一个经过验证的燃气轮机、蒸汽轮机和水轮机涡轮机控制和保护系统。Advant Controller 160 的广泛参考案例包括由 Alstom 和前 ABB Stal(现为 Siemens Industrial Turbomachinery)交付的联合循环发电站。Advant Controller 160 提供强大的功能: 逻辑和顺序控制 监管控制 定位计算和过程优化 报警和事件记录 通过串行线路(如 Modbus、SERCOS 和 Siemens 3964R)与其他系统的开放接口 应用程序和工程访问的密码保护 可扩展冗余Advant Controller 160 提供多种功能,例如:由于准确的源头事件时间标记,支持事件序列。冗余:处理器模块、I/O 总线扩展、Advant 现场总线 100 和电源。完全集成在系统 800xA 中。最多 6 个处理器模块的多处理。范围广泛的中央 S600 和分布式 S800 I/O 模块提供了最大的配置可能性。建议的最大容量约为 1500 个 I/O 点。

ABB SCYC51020 58052582H 脉冲输入(PI)模块

High-density relay switch: The module provides high-density relay switch capability and can control multiple relay channels at the same time. It supports up to 128 relay channels and is suitable for applications that need to operate multiple channels at the same time. High-speed switching operation: This module has fast relay switching speed, which can realize fast switching and connection operation. It adopts high-performance relay technology, which can complete the switching operation in milliseconds, and is suitable for applications that require high response time. Multiple relay types: Support different types of relays, including general relay, matrix relay and high-power relay. Users can choose the appropriate relay type according to specific needs, and make flexible configuration and connection. High voltage and high current measurement: This module supports high voltage and high current measurement applications. It provides high-voltage and high-current input channels, can safely measure and control high-voltage and high-current signals, and is suitable for power, electronic equipment testing and control and other application fields. The powerful software support module is equipped with NI-DAQmx driver software, which provides rich functions and easy-to-use programming interface. Users can use LabVIEW, C/C++, Python and other common programming languages to program and control, and realize relay switch operation conveniently and quickly.

Advant Controller 160 for Advant Master DCS supports and migrates ABB Advant Controller 160 for Advant Master DCS, which is a proven turbine control and protection system for gas turbines, steam turbines and water turbines. The extensive reference cases of Advant Controller 160 include combined cycle power stations delivered by Alstom and former ABB Stal (now Siemens Industrial Turbo Machinery). Advant Controller 160 provides powerful functions: logic and sequence control, supervision, control, positioning calculation and process optimization, alarm and event recording, open interface application with other systems through serial lines (such as Modbus, SERCOS and Siemens 3964R) and password protection for engineering access. Extensible redundant Advant Controller 160 provides multiple functions, such as supporting event sequence due to accurate time stamp of source events. Redundancy: processor module, I/O bus expansion, Advant field bus 100 and power supply. Fully integrated in the system 800xA. Multi-processing of up to 6 processor modules. A wide range of central S600 and distributed S800 I/O modules provide the greatest configuration possibilities. The recommended maximum capacity is about 1500 I/O points.