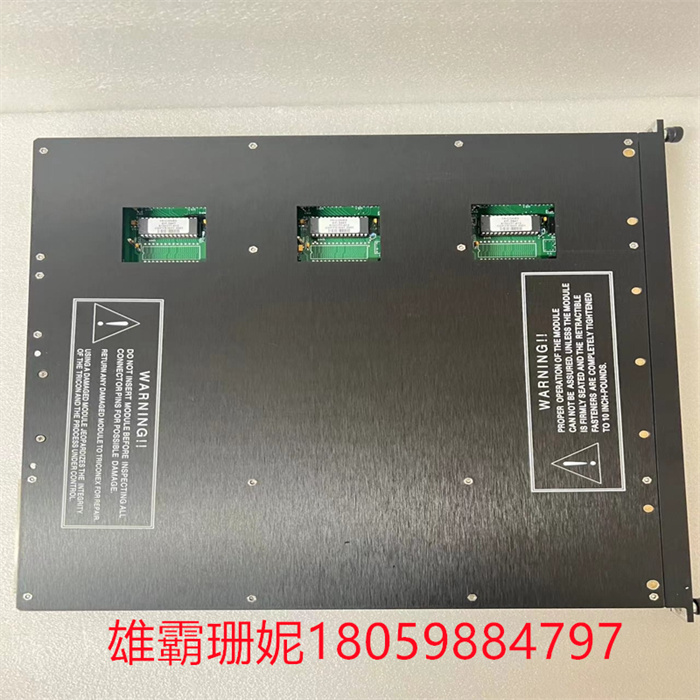

TRICONEX 3511 通讯模块

TRICONEX 3511 Invensys控制系统 通讯模块输出回路设计注意事项:3.1、输出方式选择(1)继电器输出:优点是不同公共点之间可带不同的交直流负载,且电压也可不同,带负载电流可达2A 点;但继电器输出方式不适用于高频动作的负载,这是由继电器的寿命决定的 (2)晶闸管输出:带负载能力为0.2A/ 点,只能带交流负载,可适应高频动作,响应时间为 1ms (3)晶体管输出:优点是适应于高频动作,响应时间短,一般为0.2ms左右,但它只能带DC5-30V的负载,输出负载电流为0.5A/点,但每4点不得大于0.8A。当你的系统输出频率为每分钟 6 次以下时,应继电器输出,因其电路设计简单,抗干扰和带负载能力强 当频率为 10 次/min 以下时,既可采用继电器输出方式,也可采用PLC输出驱动达林顿三极管(5-10A),再驱动负载。

英维思卡件TRICONEX 3511当PLC输出带感性负载,负载断电时会对PLC的输出造成浪涌电流的冲击,为此,对直流感性负载应在其旁边并接续流二极管,对交流感性负载应并接浪涌吸收电路,可有效保护 PLC 当两个物理量的输出在 PLC内部已进行软件互锁后,在 PLC的外部也应进行互锁,以加强系统的可靠性。

1.2、负载类型 根据PLC输出端所带的负载是直流型还是交流型,是大电流还是小电流,以及PLC输出点动作的频率等因素来确定输出端采用继电器输出,还是晶体管输出,或品闸管输出不同的负载选用不同的输出方式,这对系统的稳定运行是很重要的。

TRICONEX 3511不同的PLC产品,其COM点的数量是不一样的,有的一个COM点带8个输出点,有的带4个输出点,也有带2个或1个输出点的 当负载的种类多,且电流大时,采用一个COM点带1-2个输出点的PLC产品;当负载数量多而种类少时,采用一个 COM 点带4-8 个输出点的PLC产品,这样会对电路设计带来很多方便 每个COM点处加一熔丝,1-2个输出时加 2A 的熔丝,4-8点输出的加5-10A的熔丝。

对于PLC输出不能直接带负载的情况下,必须在外部采用驱动电路:可以用三极管驱动,也可以用固态继电器或晶闸管电路驱动,同时应采用保护电路和浪涌吸收电路,且每路有显示二极管(LED)指示。印制板应做成插拔式,易于维修PLC的输入输出布线也有一定的要求,请看各公司的使用说明书。

对于小的系统,如80点以内的系统。一般不需要扩展,当系统较大时,就要扩展。不同公司的产品,对系统总点数及扩展模块的数量都有限制,当扩展仍不能满足要求时,可采用网络结构。有些厂家产品的个别指令不支持扩展模块,因此,在进行软件编制时要注意当采用温度等模拟模块时,各厂家也有一些规定,请看相关的技术手册。各公司的扩展模块种类很多,如单输入模块、单输出模块输入输出模块、温度模块、高速输入模块等。

PLC的网络设计当用PLC进行网络设计时,其难度比PLC单机控制大得多 首先你应选用自己较熟悉的机型,对其基本指令和功能指令有较深入的了解,并且指令的执行速度和用户程序存储容量也应仔细了解。否则,不能适应你的实时要求,造成系统崩溃。另外,对通信接口、通信协议数据传送速度等也要考虑。最后,还要向PLC的商家寻求网络设计和软件技术支持及详细的技术资料,至于选用几层工作站,依你的系统大小而定。

TRICONEX 3511 通讯模块

Points for attention in output loop design:

3.1, the output mode selection

(1) Relay output: The advantage is that different AC and DC loads can be brought between different common points, and the voltage can also be different, and the load current can reach 2A points; However, the relay output mode is not suitable for the load with high frequency action, which is determined by the service life of the relay. (2) Thyristor output: the load capacity is 0.8A/ point, only AC load can be brought, and the response time is 1ms. (3) Transistor output: the advantage is that it is suitable for high frequency action, and the response time is short, generally about 0.2ms, but it can only carry the load of DC5-30V, and the output load current is 0.5A/. When the output frequency of your system is less than 6 times per minute, it should be output by relay. Because of its simple circuit design, strong anti-interference and load-carrying ability, when the frequency is less than 10 times /min, you can use relay output mode or PLC output to drive Darlington transistor (5-10A) and then drive the load.

Investex TRICONEX 3511 will impact the output of PLC when the output of PLC has inductive load and the load is cut off. For this reason, the DC inductive load should be connected in parallel with the current diode, and the AC inductive load should be connected in parallel with the surge absorption circuit, which can effectively protect the PLC. When the outputs of two physical quantities have been interlocked by software inside the PLC, they should also be interlocked outside the PLC to enhance the reliability of the system.

1.2, the load type according to the PLC output load is DC or AC, is a big current or a small current, and the frequency of PLC output point action and other factors to determine whether the output terminal adopts relay output or transistor output, or different output modes are selected for different loads, which is very important for the stable operation of the system.

TRICONEX 3511 Different PLC products have different numbers of COM points. Some COM points have 8 output points, some have 4 output points, and some have 2 or 1 output points. When there are many kinds of loads and the current is large, one COM point has 1-2 output points. When the number of loads is large and the types are few, a PLC product with 4-8 output points at a COM point will be adopted, which will bring a lot of convenience to the circuit design. Each COM point will be added with a fuse, 1-2 outputs will be added with a fuse of 2A, and 4-8 outputs will be added with a fuse of 5-10A.

When the output of PLC can't be directly loaded, the driving circuit must be used externally: it can be driven by triode, solid-state relay or thyristor circuit, and at the same time, the protection circuit and surge absorption circuit should be used, and each circuit is indicated by display diode (LED). Printed boards should be plug-in, which is easy to maintain. There are also certain requirements for input and output wiring of PLC. Please see the operating instructions of each company.

TRICONEX 3511 通讯模块

For small systems, such as systems below 80 o'clock. Generally, there is no need to expand, and when the system is large, it will be expanded. The products of different companies have restrictions on the total number of system points and the number of expansion modules. When the expansion still cannot meet the requirements, the network structure can be adopted. Some manufacturers' individual instructions do not support extended modules. Therefore, when compiling software, we should pay attention to the fact that when using temperature and other analog modules, various manufacturers also have some regulations. Please refer to the relevant technical manuals. There are many kinds of expansion modules in various companies, such as single-input module, single-output module, input-output module, temperature module, high-speed input module and so on.

Network design of PLC

When using PLC for network design, it is much more difficult than PLC stand-alone control. First of all, you should choose a familiar model, have a deeper understanding of its basic instructions and functional instructions, and also carefully understand the execution speed of instructions and the storage capacity of user programs. Otherwise, it can't meet your real-time requirements and cause the system to crash. In addition, the communication interface and data transmission speed of communication protocol should also be considered. Finally, you should also seek the network design, software technical support and detailed technical information from the PLC merchants. As for the choice of several layers of workstations, it depends on the size of your system.