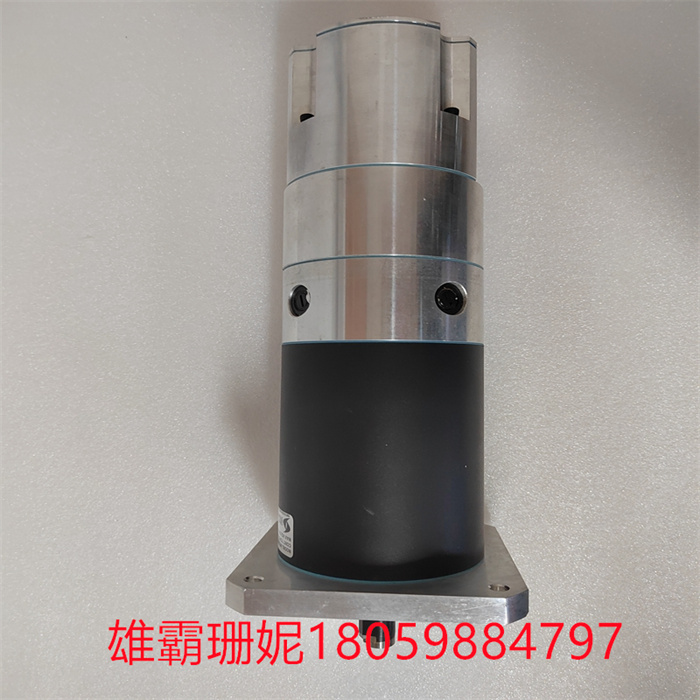

MTS30M4-38C 控制器

MTS30M4-38C 控制器

工业自动化是指机器设备或生产过程在不需要人工直接干预或较少干预的情况下,按预期的目标实现测量、操纵等信息处理和过程控制的统称。按功能划分,自动化控制具体包括控制系统、驱动系统、反馈系统、执行系统、运动控制系统等,其中的控制系统被称为是工厂的“大脑”,是工业生产尤其是流程工业的中枢和基础,其安全稳定性、效率性直接影响生产流程各个生产环节。传统控制系统一般包括仪器仪表系统、DCS系统、PLC系统、SIS系统、SCADA系统、执行调节系统等。即集散控制系统,由输入输出模块、通信模块、控制器和人机界面组成,是一种以控制器和现场设备为基础,将相关工艺信号汇集到系统中,由操作站进行监视或其他控制操作,以分散控制、集中操作、分级管理为主要特征的工业自动化控制系统。侧重于局部逻辑控制相比,DCS更注重模拟量的控制,因此DCS系统拥有更强的数据传输和管理能力,这也是大型项目广泛应用DCS系统的主要原因。

传统的控制领域正经历着一场前所未有的变革,开始向网络化方向发展。控制系统的结构从最初的CCS(计算机集中控制系统),到第二代的DCS(分散控制系统),发展到现在流行的FCS(现场总线控制系统)。对诸如图像、语音信号等大数据量、高速率传输的要求,又催生了工业以太网与控制网络的结合。

21世纪的控制系统将是网络与控制结合的系统。对网络化控制系统(Networked Control System,简称NCS)的研究已经成为当前自动化领域中的前沿课题之一。随着通信网络作为一个系统环节嵌入控制系统,这很大地丰富了工业控制技术和手段,使自动化系统与工业控制系统在体系结构、控制方法以及人机协作方法等方面都发生了较大的变化,与此同时也带来了一些新的问题,如控制与通信的耦合、时间延迟、信息调度方法、分布式控制方式与故障疹断等。

MTS30M4-38C 控制器

在控制系统中,仪器仪表作为其构成元素,它的技术进展是跟随控制系统技术的发展而发展的。目前,控制理论已发展到智能控制的新阶段,自动化仪器仪表的智能化就成为必然了。

仪器仪表的智能化主要归结于微处理器和人工智能技术的发展与应用。

例如运用神经网络、遗传算法、进化计算、混沌控制等智能技术,使仪器仪表实现高速、高效、多功能、高机动灵活等性能。

再如,运用模糊规则的模糊推理技术,对事物的各种模糊关系进行各种类型的模糊决策。

又如,用软件实现信号滤波,如快速傅立叶变换、短时傅立叶变换、小波变换等技术,是简化硬件,提高信噪比,改善传感器动态特性的有效途径。

还如,充分利用人工神经网络技术强有力的自学习、自适应、自组织能力,联想、记忆功能以及对非线性复杂关系的输入、输出间的黑箱映射特性等。

当前,我国智能化领域最薄弱、最需要发展的是仪器、仪表、传感器等基础产业。随着科学技术的飞速发展和自动化程度的不断提高,我国仪器仪表行业也将发生新的变化并获得新的发展。仪器仪表产品的高科技化,特别是智能化,将成为日后仪器仪表科技与产业的发展主流。

MTS30M4-38C 控制器

Industrial automation refers to the collective name that machinery, equipment or production process can realize information processing and process control such as measurement and manipulation according to the expected goal without direct or less manual intervention. According to the function, automatic control includes control system, drive system, feedback system, execution system, motion control system, etc. The control system is called the "brain" of the factory, which is the center and foundation of industrial production, especially process industry, and its safety, stability and efficiency directly affect all production links of the production process. Traditional control systems generally include instrumentation system, DCS system, PLC system, SIS system, SCADA system, executive regulation system and so on. That is, distributed control system, which consists of input and output module, communication module, controller and man-machine interface, is an industrial automation control system based on controller and field equipment, which collects relevant process signals into the system, and is monitored or controlled by operation station, with decentralized control, centralized operation and hierarchical management as its main features. Compared with local logic control, DCS pays more attention to analog control, so DCS system has stronger data transmission and management ability, which is the main reason why DCS system is widely used in large-scale projects.

The traditional control field is undergoing an unprecedented change and is beginning to develop in the direction of networking. The structure of control system has developed from CCS (computer centralized control system) to DCS (distributed control system) of the second generation to FCS (field bus control system) which is popular now. The demand for large data volume and high-speed transmission, such as images and voice signals, has given birth to the combination of industrial Ethernet and control network.

The control system in the 21st century will be a combination of network and control. The research on Networked Control System (NCS) has become one of the frontier topics in the field of automation. As the communication network is embedded in the control system as a system link, it greatly enriches the industrial control technology and means, and makes great changes in the system structure, control method and man-machine cooperation method between the automation system and the industrial control system. At the same time, it also brings some new problems, such as the coupling of control and communication, time delay, information scheduling method, distributed control mode and fault burst.

MTS30M4-38C 控制器

In the control system, instruments and meters are its constituent elements, and its technical progress follows the development of control system technology. At present, the control theory has developed to a new stage of intelligent control, and the intelligentization of automatic instruments and meters has become inevitable.

The intellectualization of instruments and meters is mainly attributed to the development and application of microprocessor and artificial intelligence technology.

For example, using intelligent technologies such as neural network, genetic algorithm, evolutionary computation and chaos control, instruments and meters can achieve high speed, high efficiency, multi-function and high flexibility.

Another example is the use of fuzzy reasoning technology of fuzzy rules to make various types of fuzzy decisions on various fuzzy relations of things.

For another example, using software to realize signal filtering, such as fast Fourier transform, short-time Fourier transform and wavelet transform, is an effective way to simplify hardware, improve signal-to-noise ratio and improve sensor dynamic characteristics.

For example, make full use of the powerful self-learning, self-adaptation and self-organization capabilities of artificial neural network technology, the functions of association and memory, and the black-box mapping characteristics between input and output of nonlinear complex relationships.

At present, the basic industries such as instruments, meters and sensors are the weakest and most in need of development in the field of intelligence in China. With the rapid development of science and technology and the continuous improvement of automation, China's instrument industry will also undergo new changes and obtain new development. High-tech instrumentation products, especially intelligence, will become the mainstream of instrumentation technology and industry in the future.

主营产品,供应,充足库存

Foxbore (福克斯波罗) : I/A Series 系统,FBM 全系列(现场输入/输出模块)

顺序控制、梯形逻辑控制、事故追忆处理、数模转换、输入/输出信号处理、数据通信及处理等。

Vestinghouse (西屋) : 1C31 系列DCS系统、CPU、OVATI0N 系统、WDPF系统、WEStation系统备件。

Triconex (英维思) :冗余容错控制系统、基于三重模件冗余(TMR) 结构的现代化的容错控制器。

EMERSON (艾默生) :模块、卡件、驱动器等各类备件。

XYCOM: XVME 系列

Bently (本特利) : 3500/3300 系统。

Rockwell (罗克韦尔) : ICS 系统。;

ABB: PM全系列DCS系统、ICT高压变频器系列、工业机器人备件DSQC系列、INFI 90等。

Bailey (贝利) : BRC 系列DCS系统等。

Allen-Bradley: 1756、 1785、 1771、 1746 全系列系统等。

Yokogawa (横河) : CP系列等。

Honeywell (霍尼韦尔) : TK/TC/CC 系统等。

Reliance (瑞恩) : 57C 系列等。

Modicon (莫迪康) : AS系列PLC系统备件。

MOORE,西某子数控系统等。

Motorola (摩托罗拉) : MVME 162、 MVME 167、 MYVME1772、MVME177等系列。

XYCOM: I/0、VmeE 板和处理器等。

GE (通用电气) : IC698/IC697 全系列PLC系统、模块、卡件、驱动器等各类备件。

Yaskawa (安川) :伺服控制器、伺服马达、伺服驱动器。

Bosch Rexroth (博世力士乐) : Indramat, I/O模块,电机,PLC控制器,驱动模块等。

Woodward (伍德沃德) : SPC 阀位控制器、PEAK150 数字控制器。

WINGREEN 自动化控制模块