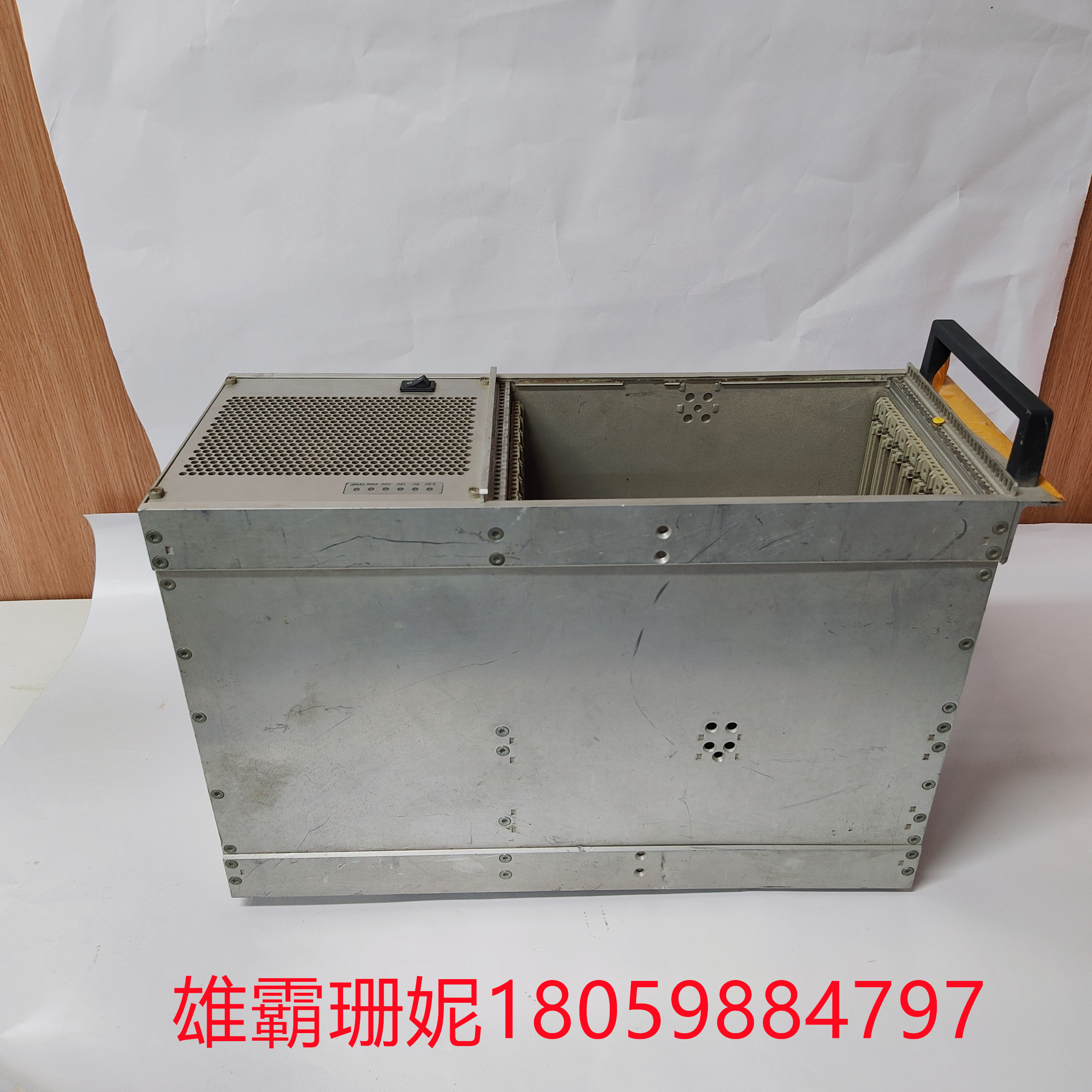

GE 20836416 可编程控制框架模块

GE 20836416 可编程控制框架模块

20836416 ESP10B ITM11A8XJ036645 GE 允许客户灵活地创建过程解决方案

GE Fanuc智能平台宣布推出PAC8000控制器。配有PAC8000控制器的Proficy过程系统为客户提供了强大而灵活的分布式控制系统(DCS)。凭借广泛的过程控制功能块库、控制器之间的点对点通信、即时处理程序和I/O更改的能力、HART通过和冗余,控制器为现代DCS解决方案提供了理想的平台。这些系统将提高运营绩效和生产率,并为客户的业务提供可持续的优势。石油和天然气、石化、生物燃料和电力需求系统等流程行业,为危险区域需求提供高可用性控制、资产管理解决方案和本质安全I/O,并为流程自动化和功能安全需求提供集成解决方案。PAC8000控制器提供所有这些功能,当与GE Fanuc的Proficy过程系统结合时,将为客户提供具有无与伦比的灵活性的坚固的DCS系统,并能够根据其特定的应用要求定制控制解决方案。PAC8000控制器提供紧密的控制回路响应,并提供广泛的过程控制功能块库。它们是开放式控制器,允许客户灵活地创建过程解决方案。PAC8000控制器可以到达其他控制器通常无法到达的地方。它们可以现场安装并经受极端情况,包括以下情况:

–40°C至+70°C工作温度范围

ISA级腐蚀

30克震动和5克振动

在I级、2区和2区危险区域运行,现场布线延伸至1区和1/0区,PAC8000控制器可将HART信息从智能现场设备传送至运行设备资产管理软件的计算机,从而实现远程维护和校准。HART数据和诊断也可直接用于控制应用,减少调试时间、过程停机时间和回路维护成本。控制器冗余提高了应用程序可用性,冗余控制器安装在同一个托架中,占用空间更小。冗余控制器并行运行,在整个处理循环中多次检查状态,使备用控制器能够持续监控主控制器的健康状况,从而确保在需要时快速、无干扰地切换。

GE 20836416 可编程控制框架模块

20836416 ESP10B ITM11A8XJ036645 GE allows customers the flexibility to create process solutions

GE Fanuc Intelligent Platform announces the launch of the PAC8000 controller. Proficy Process systems with PAC8000 controllers provide customers with a powerful and flexible distributed control system (DCS). With an extensive library of process control functional blocks, point-to-point communication between controllers, the ability to handle program and I/O changes in real time, HART pass and redundancy, controllers provide the ideal platform for modern DCS solutions. These systems will improve operational performance and productivity and provide sustainable benefits to customers' businesses. Process industries such as oil and gas, petrochemicals, biofuels and power demand systems provide high-availability control, asset management solutions and intrinsically safe I/O for hazardous zone needs, as well as integrated solutions for process automation and functional safety needs. The PAC8000 controller offers all of these capabilities and, when combined with GE Fanuc's Proficy Process system, will provide customers with a rugged DCS system with unmatched flexibility and the ability to customize control solutions to their specific application requirements. The PAC8000 controller provides tight control loop response and offers an extensive library of process control function blocks. They are open controllers that allow customers the flexibility to create process solutions. The PAC8000 controller can go where other controllers usually can't. They can be installed on-site and withstand extreme conditions, including the following:

Operating temperature range - 40°C to +70°C

ISA grade corrosion

30 grams of vibration and 5 grams of vibration

Operating in Class I, Zone 2 and Zone 2 hazard areas, with field cabling extending to Zone 1 and Zone 1/0, the PAC8000 controller transmits HART information from the intelligent field equipment to the computer running the equipment asset management software for remote maintenance and calibration. HART data and diagnostics can also be used directly for control applications, reducing debugging time, process downtime, and loop maintenance costs. Controller redundancy improves application availability, as redundant controllers are installed in the same carriage and take up less space. Redundant controllers run in parallel, checking status multiple times throughout the processing cycle, enabling the standby controller to continuously monitor the health of the primary controller, ensuring a fast and distract-free switch when needed.

GE 20836416 可编程控制框架模块