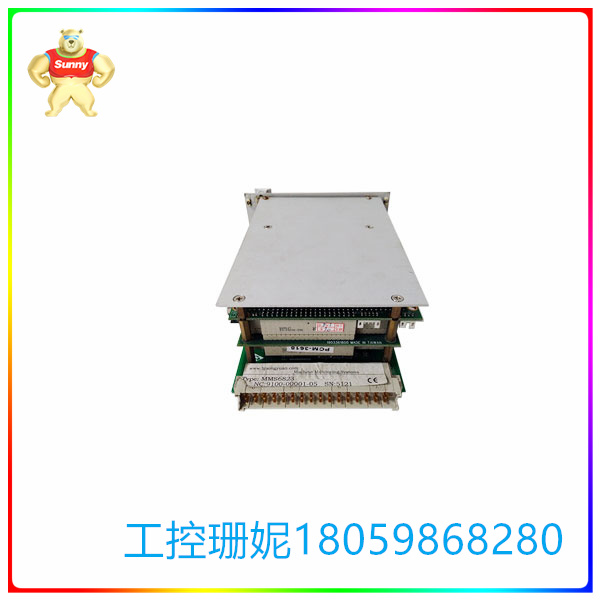

☆型号:MMS6823 机械振动数据采集模件 两种总线输出

【产品详情】

MMS6823特点:

l8路RS 485输入

l数据输出方式:

– MODBUS RTU/ASCII

– 以太网TCP/IP

l两种总线输出方式并行,相互间不影响。

l MODBUS总线的输出方式

RTU/ASCII可任选。可传输特征值,模件实时波形数据,以及模件状态和报警状态等物理量。

l键相信号调整功能

l冗余电源输入

l采用标准的19”框架模件

MMS6823旋转机械振动数据采集模件是德国EPRO公司生产的MMS6000汽轮发电机组振动监测保护系统的配套产品。系统具有实时数据采集、处理、传输等功能。它广泛适用于电力、石化、煤矿和冶金等行业的大中型旋转机械,如:汽轮发电机组、水轮机、电动机、压缩机、泵和风机等。

该模件包括数据采集和数据传输功能。与MMS6000系列模件进行RS485

数据通讯,实现数据采集和相关的设定;基于TCP/IP的数据传输可以实现远程控制,远程监视,远程配置,远程调试的功能。

MMS6823 EPRO旋转机械振动监测数据采集和通讯模件用于收集和通信旋转机械的振动监测数据。

特征

8路RS 485输入

数据输出方式:

-MODBUS RTU/ASCII

-以太网TCP/IP

两种总线输出方式并行,相互间不影响。

MODBUS总线的输出方式

RTU/ASCII可任选。可传输特征值,模件实时波形数据,以及模件状态和报警状态等物理量。

键相信号调整功能

冗余电源输入

采用标准的19”框架模件

MMS6823 EPRO模块是一种高性能设备,用于收集和传输旋转机械的振动数据。它提供了对振动信号的精确测量和分析,能够及早发现潜在问题并制定有效的维护计划。

MMS6823通过RS485总线不断地访问连接在总线上的MMS6000模件来实现数据实时采集功能,同时将接收到特征值数据和报警及模件状态数据转换成标准MODBUS协议和TCP/IP协议输出。

MMS6823通过RS-485通讯口与MMS6000汽轮机监测保护系统的RS485总线连接,获取MMS6000系统各测量模件的实时数据。由于数据直接取自测量模块,无需中间处理,因而具有其它采样方式无可比拟的精度。系统采用同步整

周期方式采集数据,采样点数可选,最大采样点数为1024。可采集起/停机(瞬态)和稳态的振动数据及相关过程参数。系统从瓦振和轴振得到动态信号,从轴位移、偏心和差胀测量模件等得到静态信号。从转速模件获得设备的转速和键相信号。

数据采集,通讯服务程序采用多线程技术,各MMS6000模件通道的数据读写操作全部并行化,每一个串口都由一个单独的线程来完成读写工作,保证通道之间的数据是同步的。

据输出分为Modbus和TCP/IP通讯。通过局域网按照TCP/IP通讯协议将实时数据送到MMS6851服务器,同时将接收到的实时数据转换成标准MODBUS协议(RTU或ASCII)以供DCS或DEH等系统的通讯使用。

Modbus协议:第一串口RS232为Modbus通讯端口,MODBUS输出可以选择MODBUS RTU或MODBUS ASCII协议方式,协议方式可由XML配置文件的Modbus字段来设定。从MMS6000接收到特征值数据和报警及模件状态数据可以被与MMS6823相连的DCS,DEH等系统访问。

TCP/IP协议:MMS6823将接收到的特征值数据、波形数据和报警及模件状态数据转换成标准TCP/IP协议,可通过以太网TCP/IP接口输出。这些数据可以被与之相连的振动分析系统访问并调用显示。TCP/IP网络接口为标准RJ45接口,使用标准网络连接电缆。MMS6823能自动检测TCP连接状态,由于软件或硬件的原因导致连接断开,监听线程能立刻检测到,并做出相应的指示。TCP端口允许一个客户端连接监听,完成系统的配置,调试和数据通讯。MMS6823的IP地址可以跟据需要灵活设置。

☆型号:MMS6823 机械振动数据采集模件 两种总线输出

【英文介绍】

MMS6823 Features:

l8 RS 485 input

l Data output mode:

– MODBUS RTU/ASCII

- Ethernet TCP/IP

The two bus output modes are parallel and do not affect each other.

l MODBUS Output mode of the bus

RTU/ASCII Optional. It can transmit characteristic values, real-time waveform data of modules, and physical quantities such as module status and alarm status.

l key trust number adjustment function

l Redundant power input

l Using standard 19 "frame modules

MMS6823 vibration data acquisition module of rotary machinery is a supporting product of MMS6000 vibration monitoring and protection system of steam turbine generator set produced by EPRO. The system has the functions of real-time data acquisition, processing and transmission. It is widely used in power, petrochemical, coal and metallurgical industries of large and medium-sized rotating machinery, such as: turbine generator set, hydraulic turbine, motor, compressor, pump and fan.

The module includes data acquisition and data transmission functions. RS485 with MMS6000 series modules

Data communication, data acquisition and related Settings; The data transmission based on TCP/IP can realize the functions of remote control, remote monitoring, remote configuration and remote debugging.

MMS6823 EPRO Vibration Monitoring Data acquisition and communication module is used to collect and communicate vibration monitoring data of rotating machinery.

trait

Eight RS 485 inputs

Data output mode:

-MODBUS RTU/ASCII

- Ethernet TCP/IP

The two bus output modes are parallel and do not affect each other.

MODBUS Indicates the output mode of the bus

RTU/ASCII Optional. It can transmit characteristic values, real-time waveform data of modules, and physical quantities such as module status and alarm status.

Key key adjustment function

Redundant power input

Standard 19 "frame modules are used

The MMS6823 EPRO module is a high-performance device for collecting and transmitting vibration data of rotating machinery. It provides accurate measurement and analysis of vibration signals, enabling early detection of potential problems and effective maintenance planning.

The MMS6823 continuously accesses the MMS6000 module connected to the bus through the RS485 bus to realize the real-time data acquisition function, and converts the received feature value data, alarm and module status data into standard MODBUS and TCP/IP protocol output.

MMS6823 is connected to RS485 bus of MMS6000 steam turbine monitoring and protection system through RS-485 communication port to obtain real-time data of each measurement module of MMS6000 system. Because the data is taken directly from the measurement module, there is no intermediate processing, so it has an unparalleled accuracy of other sampling methods. The system adopts synchronous integration

Data is collected periodically. The sampling number is optional. The maximum sampling number is 1024. Vibration data and related process parameters for start/stop (transient) and steady state can be collected. The system obtains dynamic signals from tile vibration and shaft vibration, and static signals from axial displacement, eccentricity and differential expansion measurement modules. Get the device's speed and key trust number from the speed module.

Data acquisition, communication service program using multi-thread technology, each MMS6000 module channel data read and write operations are all parallel, each serial port by a separate thread to complete the read and write work, to ensure that the data between the channels is synchronized.

The output is divided into Modbus and TCP/IP communication. The real-time data is sent to the MMS6851 server through the LAN according to TCP/IP communication protocol, and the received real-time data is converted into the standard MODBUS protocol (RTU or ASCII) for the communication of DCS or DEH system.

Modbus protocol: The first serial port RS232 is the Modbus communication port. MODBUS output can be MODBUS RTU or MODBUS ASCII protocol. The protocol mode can be set by the Modbus field in the XML configuration file. The eigenvalue data and alarm and module status data received from the MMS6000 can be accessed by DCS, DEH and other systems connected to the MMS6823.

TCP/IP protocol: MMS6823 converts the received eigenvalue data, waveform data, alarm and module status data into standard TCP/IP protocol, which can be output through Ethernet TCP/IP interface. These data can be accessed and displayed by the connected vibration analysis system. The TCP/IP network interface is a standard RJ45 port and uses a standard network connection cable. MMS6823 can automatically detect the TCP connection status, due to software or hardware reasons to disconnect, the listening thread can immediately detect, and make the corresponding instructions. TCP ports allow a client connection to listen, complete system configuration, debugging, and data communication. The IP address of the MMS6823 can be flexibly set as required.

☆型号:MMS6823 机械振动数据采集模件 两种总线输出

【其他型号推荐】

| ABB SDCS-CON-4 2 | KEMRO K2-400 CP 450C | IS215UCVGH1A C VMIVME-7666-111000350-017666-111000 C | TCSESM043F2CS0 - | SE00-11-PKZ0 PLC |

| ABB SPBRC410 | EMERSON KJ1710X1-BA1 | IS215UCVGM06A IS215UCVGH1A VMIVME-7666-111000 | TE 1605341 VER02 1605340-05 | SFCA256GH1AD4TO-I-HT-216-STD PLC |

| ABB SPIET800 1 | EMERSON KJ2003X1-BB1 | MC91 HESG440588R4 HESG112714B | TK457V050 3BSE004394R1 | SP-240-24 PLC |

| ABB TC520 2 | KJ2201X1-PW1 | MOTOROLA MVME5100 | TK-FPDXX2 | SPW482-13-S1 YOKOGAWA |

| ABB UFC760BE1142 3BHE0Q4573R1142 | KJ3002X1-BF1 | NF93a-2 HESG440280R2 | TK-FTEB01 51309512-175 - | Schneider TM251MESC |

| ABB UNITROL 1010 3BHE035301R1002 UNS0121A-Z,V1 1 | KJ3002X1-BG2. | PFSA140 3BSE006503R1 | TK-IOLI01 51403427-175 | TS35X7 plc |

| ABB XV9738a HEIE450617R 1 | KJ3003X1-EA1 | 3BHB003688R0101 | TK-PRR021 51309288-275 | BELIMO VFP-100 |

| DELTA TAU ACC-24E2-2CH | KJ3241X1-BA1 | NAI 64SD1-08KRF1 | TK-PRS021 51404305-275 | PAPST W2E200-HK38-01 |

| Allen-Bradley 6186-M15ALTR 1 | EMERSON KJ4001X1-CC1 | HE700GEN100C | TP830-1 3BSE018115R1 | WF20 DR63S4 plc |

| Allen-Bradley 1394-SJT22-T-RL | KJ4001X1-CG1 | HE700GEN200C | TP854 TRICONEX | ХACB041 plc |

| Allen-Bradley 1764-LSP 1 | KJ4001X1-CK1 | IC660ELB912J | TP854 3BSE025349R1 | 1746-IB16 |

| Allen-Bradley 2711-K5A16 1 | KJ4002X1-BE1 | PPC902AE101 3BHE010751R0101 | TPMC815-11 | 1746-IB32 |