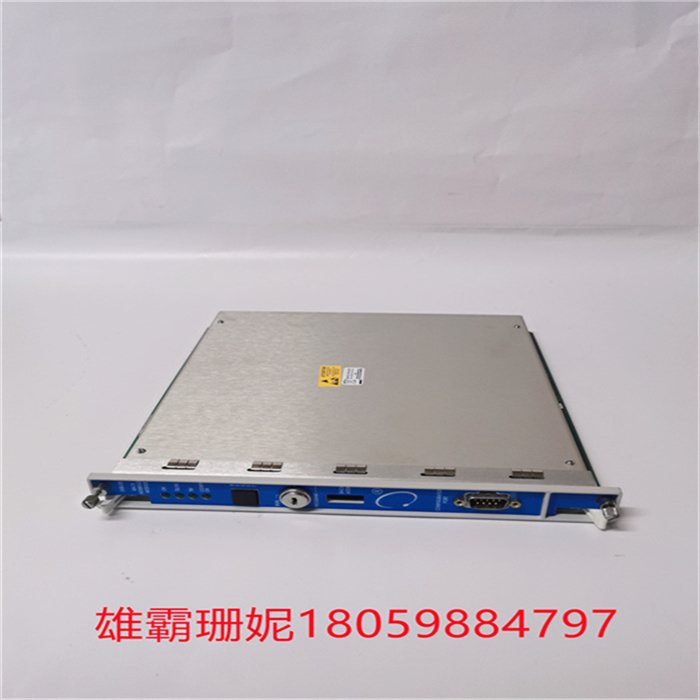

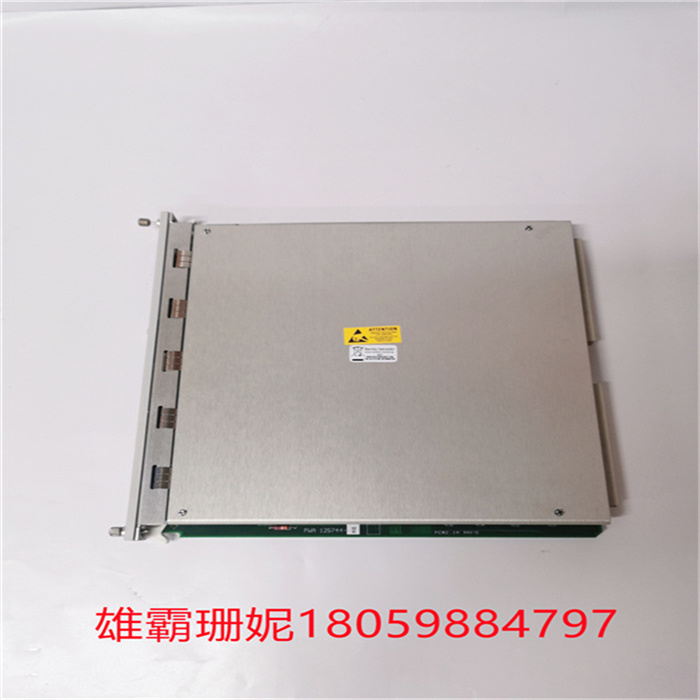

BENTLY 350020 125744-02 径向振动卡件

Bently Nevada 的 4 通道 3500/70M Recip 脉冲/速度监视器:

从地震传感器(例如 Bently Nevada 330400、330425 和 Velomitor CT)接收加速度和速度输入。

调节信号以接收振动测量结果,并将测量到的变量与用户可编程警报进行比较。

根据需要设置脉冲加速度、加速度 2、往复速度和低频往复速度通道功能。

3500 系统可作为 SIL 2 级系统使用,并获得多个危险区域和特定国家/地区的批准。

我们的 4 通道 3500/72 Recip 杆位置监测器 处理来自 Bently Nevada Proximitor 传感器的信号,以创建针对活塞杆位置监测优化的测量结果。提供对往复式压缩机状况的重要洞察。此外,每个通道都可以编程来执行杆位置测量、杆下落测量和超压缩机测量。3500 系统可作为 SIL 2 级系统使用,并获得多个危险区域和特定国家/地区的批准。

4 通道 3500/77M 往复气缸压力监测器:

优化监控 - 接受来自本特利内华达州 165855 认证的独特气缸压力传感器的输入,生成一系列优化的测量值,用于监控 API-618 服务中的往复式压缩机的状况。

测量性能和诊断 - 与 System 1 软件和多事件轮相结合,基于动态压力的测量可适应压缩机热力学性能监控以及用于识别机器故障模式的深度诊断和故障图例。

提供多种测量变量 - 3500/77M 测量的气缸操作变量包括最大和最小压力、排出压力、吸入压力、压缩比、峰值杆压缩、峰值杆张力和杆反转程度。

BENTLY 350020 125744-02 径向振动卡件

Bently Nevada's 4-channel 3500/70M Recip Pulse/Speed Monitor;

Receive acceleration and velocity inputs from seismic sensors, such as Bently Nevada 330400, 330425 and Velomitor CT.

Adjust the signal to receive the vibration measurement and compare the measured variable with the user programmable alarm.

Set pulse acceleration, acceleration 2, reciprocating speed and low frequency reciprocating speed channel functions as required.

The 3500 system can be used as a SIL 2 level system, and has been approved by several hazardous areas and specific countries/regions.

Our 4-channel 3500/72 Recip rod position monitor processes signals from Bently Nevada Proximitor sensors to create optimized measurement results for piston rod position monitoring. Provide important insight into the condition of reciprocating compressor. In addition, each channel can be programmed to perform rod position measurement, rod drop measurement and ultracompressor measurement. The 3500 system can be used as a SIL 2 level system, and has been approved by several hazardous areas and specific countries/regions.

4-channel 3500/77M reciprocating cylinder pressure monitor;

Optimized monitoring-receives the input from the unique cylinder pressure sensor certified by Bentley Nevada 165855, and generates a series of optimized measurement values for monitoring the condition of reciprocating compressor in API-618 service.

Measurement performance and diagnosis-Combined with System 1 software and multi-event wheel, the measurement based on dynamic pressure can adapt to compressor thermodynamic performance monitoring, deep diagnosis and fault legend for identifying machine fault modes.

Provide a variety of measurement variables-3500/77M The measured cylinder operating variables include maximum and minimum pressure, discharge pressure, suction pressure, compression ratio, peak rod compression, peak rod tension and rod reversal degree.